Description

VRLA technology

VRLA stands for Valve Regulated Lead Acid, which means the batteries are sealed. Gas will escape through the safety valves only in case of overcharging or cell failure. VRLA batteries are maintenance free for life.

Sealed (VRLA) AGM batteries

AGM stands for Absorbent Glass Mat. In these batteries, the electrolyte is absorbed into a glass-fiber mat between the plates by capillary action. As explained in our book ‘Energy Unlimited’, AGM batteries are more suitable for short-time delivery of very high currents (engine starting) than gel batteries.

Sealed (VRLA) Gel batteries

Here the electrolyte is immobilized as gel. Gel batteries in general have a longer service life and better cycle capacity than AGM batteries.

Low Self-discharge

Low Self-discharge

Because of the use of lead calcium grids and high purity materials, Victron VRLA batteries can be stored during long periods of time without recharge. The rate of self-discharge is less than 2% per month at 20°C. The self-discharge doubles for every increase in temperature with 10°C. Victron VRLA batteries can, therefore, be stored during up to a year without recharging, if kept under cool conditions.

Exceptional Deep Discharge Recovery

Victron VRLA batteries have exceptional discharge recovery, even after deep or prolonged discharge. It should, however, be stressed that repetitive deep discharge and prolonged discharge have a very negative influence on the service life of all lead-acid batteries, Victron batteries are no exception.

Battery discharging characteristics

The rated capacity of Victron AGM and Gel Deep Cycle batteries refers to 20-hour discharge, in other words: a discharge current of 0,05 C.

The rated capacity of Victron Tubular Plate Long Life batteries refers to 10 hours discharge.

The effective capacity decreases with increasing discharge current (see table 1). Please note that the capacity reduction will be even faster in case of a constant power load, such as an inverter.

| Discharg time (constant current) |

End Voltage V |

AGM ‘Deep Cycle’ % |

Gel ‘Deep Cycle’ % |

Gel ‘Long Life’ % |

|---|---|---|---|---|

| 20 hours | 0,8 | 100 | 100 | 112 |

| 10 hours | 10,8 | 92 | 87 | 100 |

| 5 hours | 10,8 | 85 | 80 | 94 |

| 3 hours | 10,8 | 78 | 73 | 79 |

| 1 hour | 9.6 | 65 | 61 | 63 |

| 30 min. | 9.6 | 55 | 51 | 45 |

| 15 min. | 9.6 | 42 | 38 | 29 |

| 10 min. | 9.6 | 38 | 34 | 21 |

| 5 min. | 9.6 | 27 | 24 | |

| 5 seconds | 8 C | 7 C |

Table 1: Effective capacity as a function of discharge time (the lowest row gives the maximum allowable 5 seconds discharge current)

Our AGM deep cycle batteries have excellent high current performance and are therefore recommended for high current applications such as engine starting. Due to their construction, Gel batteries have a lower effective capacity at high discharge currents. On the other hand, Gel batteries have a longer service life, both under float and cycling conditions.

Effect of temperature on the service life

High temperature has a very negative effect on service life. The service life of Victron batteries as a function of temperature is shown in table 2.

| Average Temperature | AGM Deep Cycle years | Gel Deep Cycle years | Gel Long Life years |

|---|---|---|---|

| 20°C / 68°F | 7 -10 | 12 | 20 |

| 30°C / 86°F | 4 | 6 | 10 |

| 40°C / 104°F | 2 | 3 | 5 |

Table 2: Design service life of Victron batteries under float service

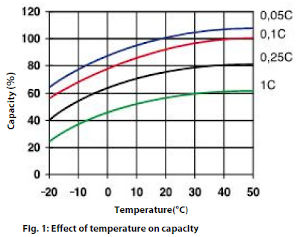

Effect of temperature on capacity

As is shown by the graph below, capacity reduces sharply at low temperatures.

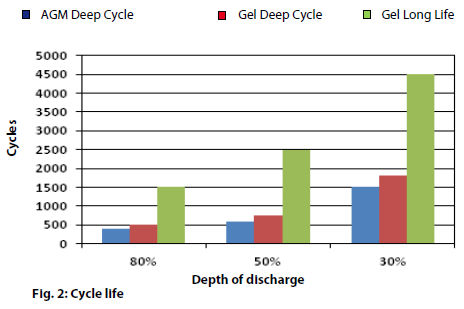

Cycle life of Victron batteries

Batteries age due to discharging and recharging. The number of cycles depends on the depth of discharge, as is shown in figure

Battery charging in case of cycle use: the 3-step charge curve

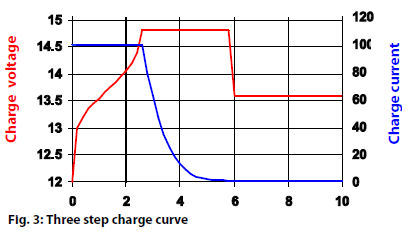

The most common charge curve used to charge VRLA batteries in case of cyclic use is the 3-step charge curve, whereby a constant current phase (the bulk phase) is followed by two constant voltage phases (absorption and float), see fig. 3.

During the absorption phase, the charge voltage is kept at a relatively high level in order to fully recharge the battery within a reasonable time. The third and last phase is the float phase: the voltage is lowered to standby level, sufficient to compensate for self-discharge.

Disadvantages of the traditional 3-step charge curve:

- During the bulk phase the current is kept at a constant and often high level, even after the gassing voltage (14,34 V for a 12 V battery) has been exceeded. This can lead to excessive gas pressure in the battery. Some gas will escape trough the safety valves, reducing service life.

- Thereafter the absorption voltage is applied during a fixed period of time, irrespective of how deep the battery has been discharged previously. A full absorption period after a shallow discharge will overcharge the battery, again reducing service life. (a. o. due to accelerated corrosion of the positive plates)

- Research has shown that battery life can be increased by decreasing float voltage to an even lower level when the battery is not in use.

Battery charging: longer battery life with Victron 4-step adaptive charging

Victron developed the adaptive charge curve. The 4-step adaptive chare curve is the result of years of research and testing.

The Victron four-step adaptive charge curve solves the 3 main problems of the 3 step curve:

- Battery Safe mode

In order to prevent excessive gassing, Victron has invented the ‘Battery Safe Mode’. The battery Safe Mode will limit the rate of voltage increase once the gassing voltage has been reached. Research has shown that this will reduce internal gassing to a safe level. - Variable absorption time

Based on the duration of the bulk stage, the charger calculates how long the absorption time should be in order to fully charge the battery. If the bulk time is short, this means the battery was already charged and the resulting absorption time will also be short, whereas a longer bulk time will also result in longer absorption time. - Storage mode

After completion of the absorption period, the battery should be fully charged, and the voltage is lowered to the float or standby level. If no discharge occurs during the next 24 hours, the voltage is reduced even further and the battery goes into storage mode. The lower storage voltage reduces the corrosion of the positive plates. Once every week the charge voltage is increased to the absorption level for a short period to compensate for self-discharge (Battery Refresh mode).

Battery charging in case of standby use: constant voltage float charging

When a battery is not frequently deeply discharged, a 2-step charge curve can be used. During the first phase the battery is charged with a limited current (the bulk phase). Once a preset voltage has been reached the battery is kept at that voltage (the float phase). This charge method is used for starter batteries in vehicles, and in uninterruptible power supplies (UPS).

Optimum charge voltage of Victron VRLA batteries

The recommended charge voltage settings for a 12 V battery are shown in table 3.

Effect of temperature on charging voltage

The charge voltage should be reduced with increased temperature. Temperature compensation is required when the temperature of the battery is expected to be less than 10°C / 50°F or more than 30°C / 85°F during long periods of time. The recommended temperature compensation for Victron VRLA batteries is -4 mV / Cell (-24 mV /°C for a 12 V battery). The center point for temperature compensation is 20°C / 70°F.

Charge current

The charge current should preferably not exceed 0,2 C (20 A for a 100 Ah battery).The temperature of a battery will increase by more than 10°C if the charge current exceeds 0,2 C. Therefore temperature compensation is required if the charge current exceeds 0,2 C.

Type Overview:

| 12 Volt Deep Cycle AGM | ||||||

|---|---|---|---|---|---|---|

| Article Number |

Ah | V | L X W x H mm |

Weight kg |

CCA @0 ºF | Res Cap @80ºF |

| BAT406225080 | 240 | 6 | 320x176x247 | 31 | 1500.0 | 480 |

| BAT212070080 | 8 | 12 | 151x65x101 | 2.5 | ||

| BAT212120080 | 14 | 12 | 151x98x101 | 4.1 | ||

| BAT212200080 | 22 | 12 | 181x77x167 | 5.8 | ||

| BAT41220080 | 38 | 12 | 197x165x170 | 12.5 | ||

| BAT412350080 | 60 | 12 | 229x138x227 | 20 | 450 | 90 |

| BAT412550080 | 66 | 12 | 258x166x235 | 24 | 520 | 100 |

| BAT412600080 | 90 | 12 | 350x167x183 | 27 | 600 | 145 |

| BAT412800080 | 110 | 12 | 330x171x220 | 32 | 800 | 190 |

| BAT412121080 | 130 | 12 | 410x176x227 | 38 | 1000 | 230 |

| BAT412151080 | 165 | 12 | 485x172x240 | 47 | 1200 | 320 |

| BAT412201080 | 220 | 12 | 522x238x240 | 65 | 1400 | 440 |

(Technology: flat plate AGM / Terminals: copper)

Rated capacity: 20 hr discharge at 25°C

Float design life: 7-10 years at 20 °C

Cycle design life:

400 cycles at 80% discharge

600 cycles at 50% discharge

1500 cycles at 30% discharge

| 12 Volt Deep Cycle GEL | ||||||

|---|---|---|---|---|---|---|

| Article Number |

Ah | V | L X W x H mm |

Weight kg |

CCA @0 ºF | Res Cap @80ºF |

| BAT412550100 | 60 | 12 | 229x138x227 | 20 | 300 | 80 |

| BAT412600100 | 66 | 12 | 258x166x235 | 24 | 360 | 90 |

| BAT412800100 | 90 | 12 | 350x167x183 | 26 | 420 | 130 |

| BAT412101100 | 110 | 12 | 330x171x220 | 33 | 550 | 180 |

| BAT412121100 | 130 | 12 | 410x176x227 | 38 | 700 | 230 |

| BAT412151100 | 165 | 12 | 485x172x240 | 48 | 850 | 320 |

| BAT412201100 | 220 | 12 | 522x238x240 | 66 | 1100 | 440 |

(Technology: flat plate AGM / Terminals: copper)

Rated capacity: 20 hr discharge at 25°C

Float design life: 7-10 years at 20 °C

Cycle design life:

400 cycles at 80% discharge

600 cycles at 50% discharge

1500 cycles at 30% discharge

| 2 Volt Long Life GEL | ||||

|---|---|---|---|---|

| Article Number |

Ah | V | L X W x H mm |

Weight kg |

| BAT702601260 | 600 | 2 | 145x206x688 | 49 |

| BAT702801260 | 800 | 2 | 210x191x688 | 65 |

| BAT702102260 | 1000 | 2 | 210x233x690 | 80 |

| BAT702122260 | 1200 | 2 | 210x275x690 | 93 |

| BAT702152260 | 1500 | 2 | 210x275x840 | 115 |

| BAT702202260 | 2000 | 2 | 215x400x815 | 155 |

| BAT702252260 | 2500 | 2 | 215x490x815 | 200 |

| BAT702302260 | 3000 | 2 | 215x580x815 | 235 |

(Technology: flat plate AGM / Terminals: copper)

Rated capacity: 10 hr discharge at 25 °C

Float design life: 20 years at 20 °C

Cycle design life:

1500 cycles at 80% discharge

2500 cycles at 50% discharge

4500 cycles at 30% discharge